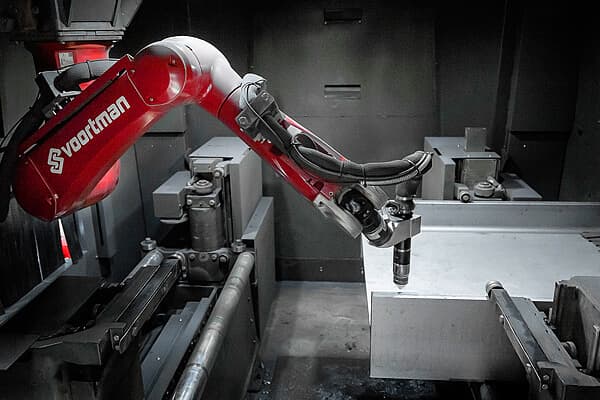

Robotic Coping Machines Explained

Dragon's front positioning gate and the chuck are easily adjustable, making it easy for you to load and arrange different shapes and sizes of materials.

Automated marking is more efficient and saves you time in your workshop. The V808 can automatically mark the four sides of the profile. Although marking only three sides of the profile is feasible, workers still have to take measurements on the fourth. Voortman can handle all four sides. This will help you save time in your workshop and reduce costs.